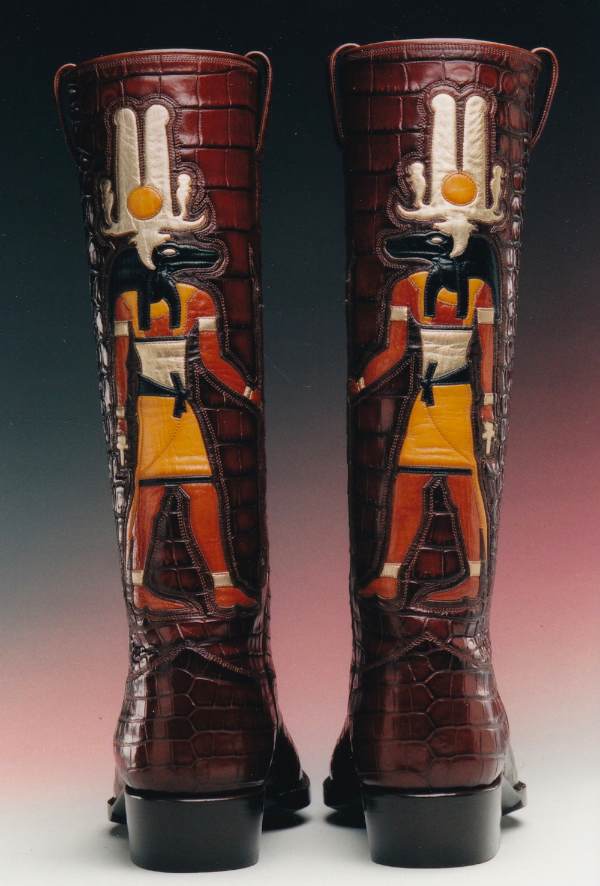

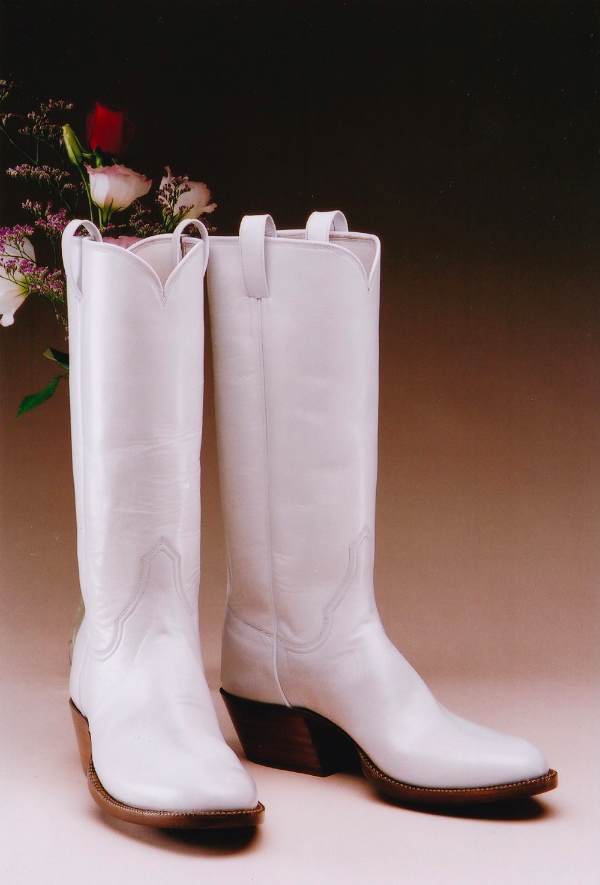

Lincoln Boots -

Authentic 19th Century Boots Brought to life in the 21th century

Carnacchi made two trips to D.C. to view the originals and got the measurements of Lincoln’s feet from a memorabilia collector in the midwest. To get the proper last, or foot model, he worked with the country’s only remaining last company. Then he carved it to Lincoln’s measurements.

“Ante-bellum boots had no toe box,” he said. “The toes went right to the end of the boot. It created a different type of gait.”

A furniture maker made “crimping” forms to stretch the leather into the right shape. Then he set about locating the right leather.

The Horween Tannery has been in business in Chicago for several generations. Carnacchi obtained “black waxed flesh” from them, then sent to Germany for the leather used in the outsole of the boots.

His stitching machines had be calibrated to the exact number of stitches per inch, generally 13. Other stitching had to be done by hand.

To duplicate the delicate crosshatching that was stamped into the leather, he had to have special metal plates made. On most of the boot, he used a 1,200 pound-per-square-inch hydraulic press to recreate the pattern. Crosshatching on the heels had to be done painstakingly by hand.

Although Lincoln’s boots were faded on the outside, Abe had spilled some oxblood polish inside while polishing them. He polished his own boots even at the White House. Carnacchi had purchased an antique shoeshine box that still contained that exact color.

To oil the boots, Carnacchi used birch tar oil, a natural bug repellent. He had smelled its distinctive odor on the originals, so the new boots even smell like Lincoln’s.